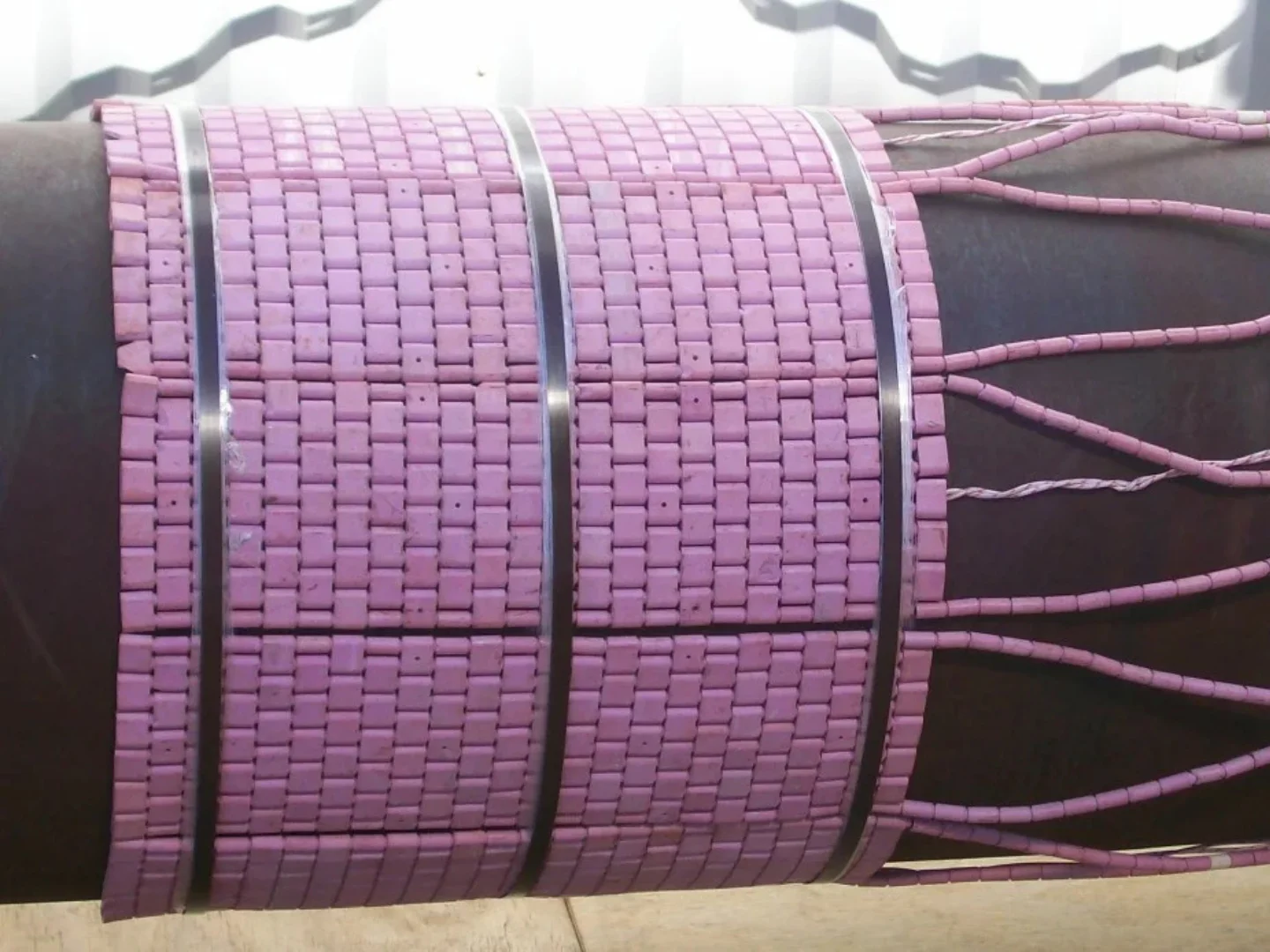

Post Weld Heat Treatment for Stress Relief and Stability

A controlled heat treatment process that reduces residual stresses and improves weld stability.

Post weld heat treatment reduces residual stresses created during welding and improves the structural stability of the material. By heating the weld and surrounding area to a controlled temperature and then cooling it gradually, the mechanical properties of the component are enhanced. This process is important for high strength materials and pressure containing systems. Our specialists ensure accurate temperature control and monitoring for reliable outcomes.

- Reduces harmful residual stresses

- Improves weld ductility and stability

- Enhances long term material performance

- Supports pressure vessel requirements

- Aids in reducing cracking risks

- Ensures compliance with engineering standards

Post weld heat treatment assists in restoring balance within welded structures by reducing internal stresses. Controlled heating and cooling improve material behaviour and help prevent cracking during service. This process is essential for components that operate under demanding conditions and require stable long term performance.

Planning & Strategy

Our PWHT strategy involves defining the correct heating cycle, temperature range, and holding time based on material type and weld size. Careful planning ensures uniform stress relief and improved structural integrity.

How We Work

Our Testing Process Made Simple

Requirement Understanding

Method Selection

Test Execution

Reporting and Review

We are always ready to help you and answer your questions