Advanced Ultrasonic Evaluation for Internal Flaw Detection

A precise method that uses sound waves to detect internal flaws and measure material thickness with high accuracy.

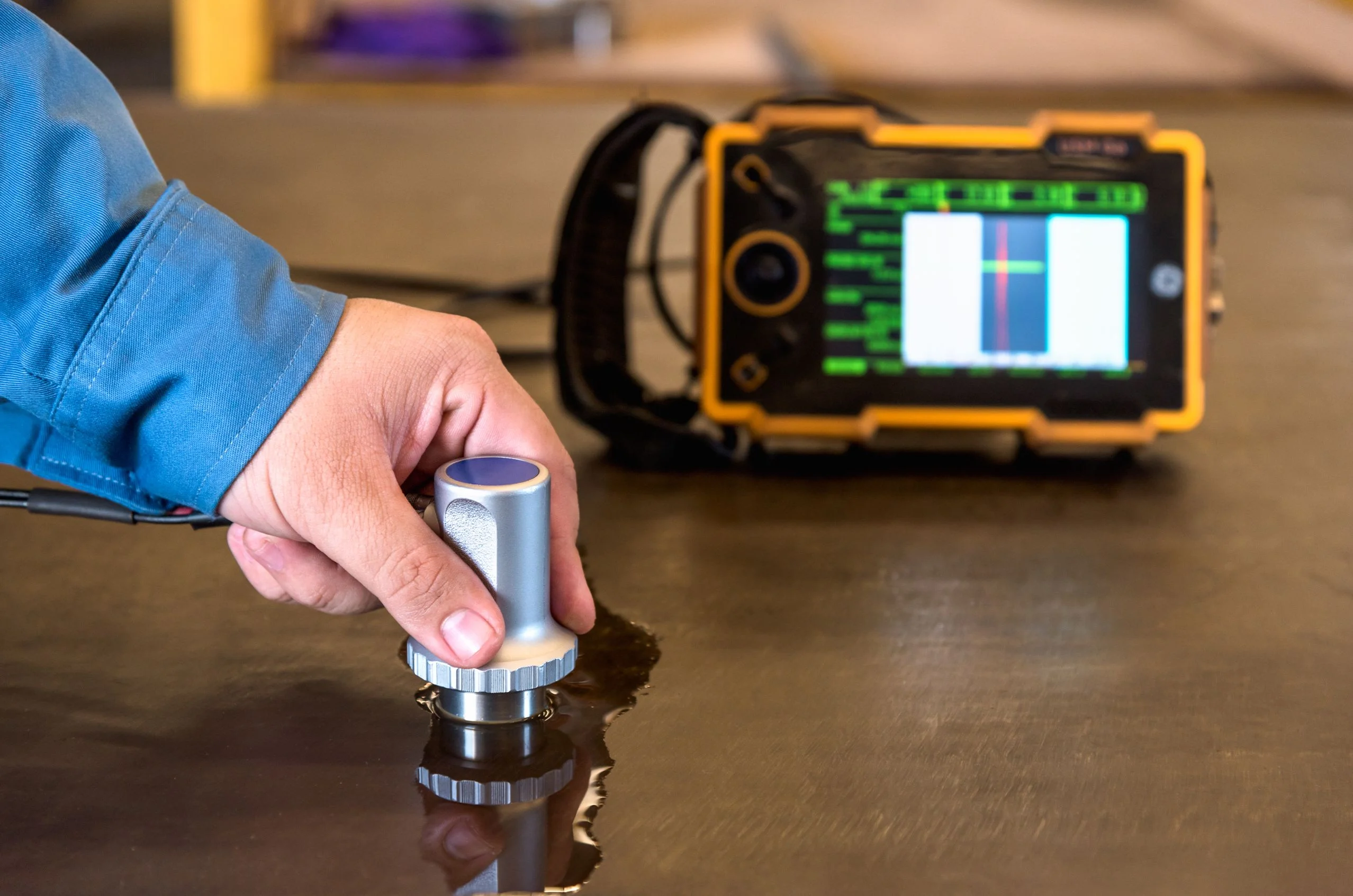

Ultrasonic testing uses high frequency sound waves to evaluate material integrity, detect internal flaws, and measure thickness with exceptional accuracy. This method is ideal for identifying hidden cracks, voids, and weld defects that cannot be seen on the surface. It is widely used across fabrication, construction, and engineering projects where reliability and safety are critical. Our trained specialists perform each inspection with calibrated equipment to ensure consistent and dependable results.

- Detects internal flaws with high accuracy

- Measures material thickness reliably

- Suitable for welds and structural parts

- Works on metals and engineered materials

- Provides fast and clear results

- Ideal for critical safety applications

Ultrasonic evaluation allows us to study the internal condition of materials without disrupting their structure. By sending controlled sound waves through a component, we identify inconsistencies that may affect long term performance. This technique supports industries that rely on dependable welds and uniform material thickness.

Planning & Strategy

Our planning process begins with reviewing material thickness, geometry, and critical areas that require internal evaluation. We choose the right ultrasonic settings and scanning approach to ensure accurate readings and dependable results for every inspection.

How We Work

Our Testing Process Made Simple

Requirement Understanding

Method Selection

Test Execution

Reporting and Review

We are always ready to help you and answer your questions